- Home

- About Us

- GAINS

- News/TAG Webinars

- Membership

- Annual Meeting/SAGEEP

- SAGEEP 2026

- SAGEEP 2026 Schedule at a Glance

- SAGEEP 2026 Registration Information

- SAGEEP 2026 Abstract/Session Schedule

- SAGEEP 2026 Sponsorship Opportunities

- SAGEEP 2026 Exhibitor Opportunities

- SAGEEP 2026 Exhibitor Contract

- SAGEEP 2026 Accommodations

- SAGEEP 2026 Short Coures

- SAGEEP 2026 Luncheons/Conference Events/Activities

- SAGEEP 2025

- SAGEEP 2025-Munitions Response Meeting Abstracts/Sessions

- SAGEEP 2025-MRM Exhibiting/Sponsorship Opportunities

- SAGEEP 2025-MRM Accommodations

- SAGEEP 2025-MRM Registration Information

- SAGEEP 2025-MRM Program

- SAGEEP 2025-Munitions Response Meeting Short Courses

- SAGEEP 2025/MRM Luncheons/Conference Events/Activities

- SAGEEP 2024

- SAGEEP 2023

- SAGEEP 2022

- SAGEEP 2021

- SAGEEP 2020 Exhibiting/Sponsorship

- SAGEEP-2019

- SAGEEP 2019 Exhibiting/Sponsorship

- SAGEEP 2018

- SAGEEP 2017

- SAGEEP 2016

- SAGEEP 2015

- Proceedings SAGEEP 2024

- Proceedings SAGEEP 2023

- Proceedings SAGEEP 2022

- Proceedings SAGEEP 2018

- Proceedings SAGEEP 2025

- SAGEEP 2026

- Publications & Merchandise

|

|

|

|

Michael May |

Rick Toomey Rick Toomey |

|

On February 12, 2014, a sinkhole opened under the floor of the Skydome area of the Corvette Museum

at around 5:44 AM local time, causing a portion of the floor to collapse.

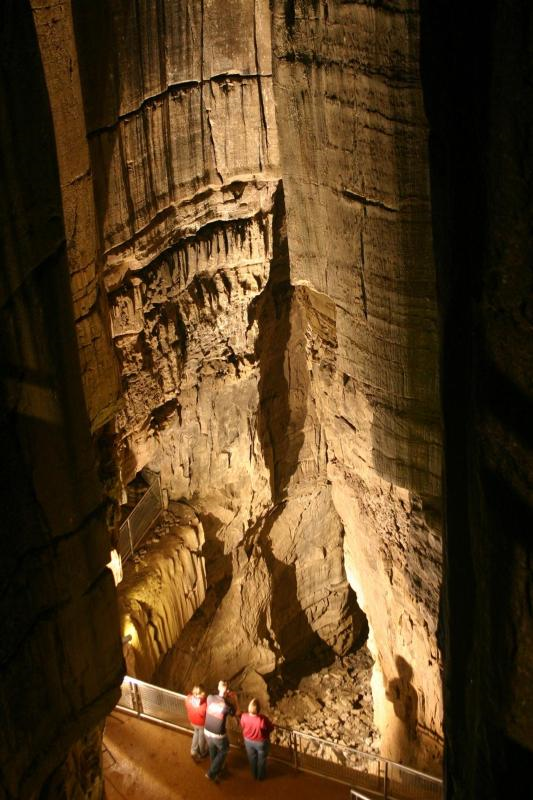

Credit: NPS Photo Mammoth Dome, inside Mammoth Cave along the Historic tour route, taken from the Mammoth

Dome tower (during the WKYU-PBS Mammoth Cave: A Way to Wonder shoot)

Thursday, March 29 7:30 a.m. to ~5:00 p.m. CDT

SAGEEP 2018 Field Trip to Center Hill and Normandy Dams

This field trip will highlight two federally owned dams which are both located in karst-prone areas in Middle Tennessee. Center Hill Dam is owned by the U.S. Army Corps of Engineers (USACE) and Normandy Dam is owned by the Tennessee Valley Authority (TVA). The field trip will end with a stop at the George A. Dickel Distillery visitor’s center.

Center Hill Dam Description

Center Hill Dam is sited at Mile 26.6 on the Caney Fork River, a major tributary to the Cumberland River. The Center Hill project was put into service in 1951 to provide important regional benefits of flood control, hydro power, recreation, water supply and water quality. The main dam consists of a 1382ft (421m) long concrete section and a 778ft (237m) long rolled earth embankment. A 770ft (235m) long saddle dam lies within a narrow valley along the right rim, about 1500ft (457m) upstream of the main dam. A three-generator-unit power plant, with a capacity of 135,000kW, and switchyard are located immediately downstream.

Geologic Setting

The site geology is characterized by numerous caves, springs, and sinks. These features are typical of the soluble limestone of the region and indicative of a well-developed karst terrain. Center Hill Dam is founded in nearly flat lying limestone and shale of Ordovician age. In ascending order, the formations present at the dam site are the Carters, Hermitage, Cannon, Catheys, and Leipers of Ordovician age, the Chattanooga of Devonian and Mississippian, and the Fort Payne of Mississippian age. The contact between the Hermitage and Cannon formation is an unconformity with a significant amount of karst development. The Catheys formation forms the upper portion of the foundation of the concrete dam and earth embankment. The Catheys is a finely crystalline to crystalline, hard, fossiliferous limestone. The contact between the Cannon and the Catheys is also an unconformity with localized karst development.

Center Hill Dam Karst-related Issues

Limestone karst seepage has been an issue with operation of the USACE’s Center Hill Dam since construction of the project in the 1940s. Project designers acknowledged the cave-scattered region would require future grouting to control seepage through the well-developed bedrock joint system. Despite several localized grouting efforts over the years, total seepage increased to unprecedented levels under normal reservoir conditions. Foundation conditions deteriorated in the clay-filled rock joints within the rims, the abutments and the dam’s foundation to the point that USACE initiated a major rehabilitation project to address these concerns.

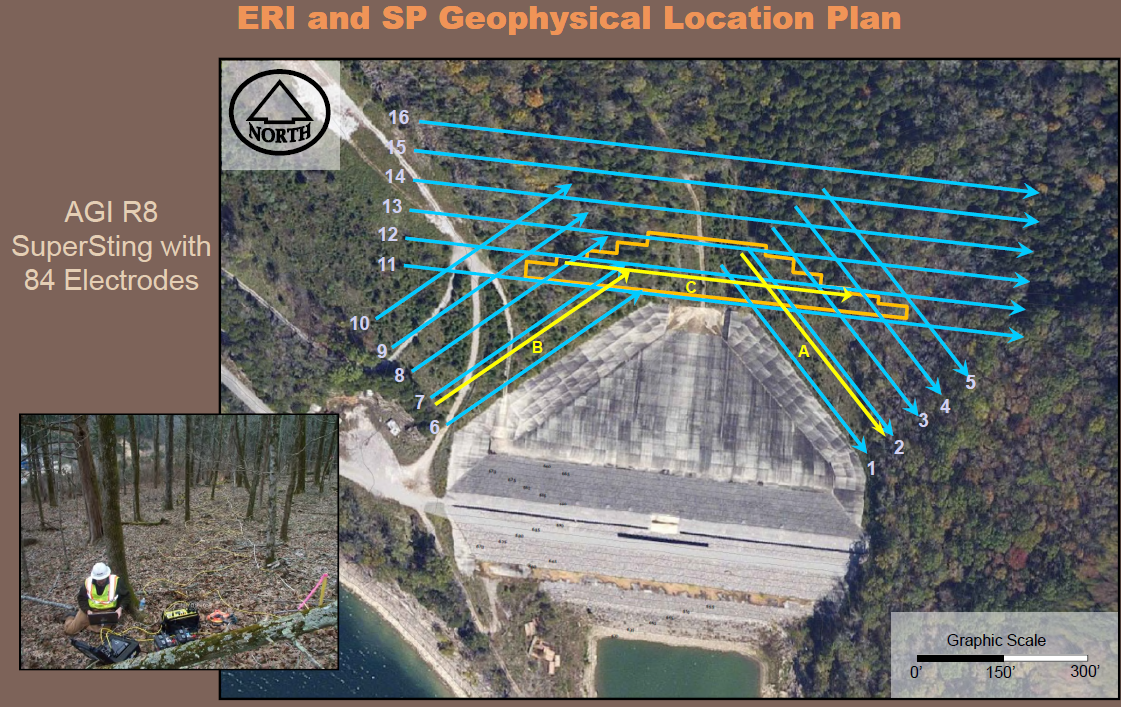

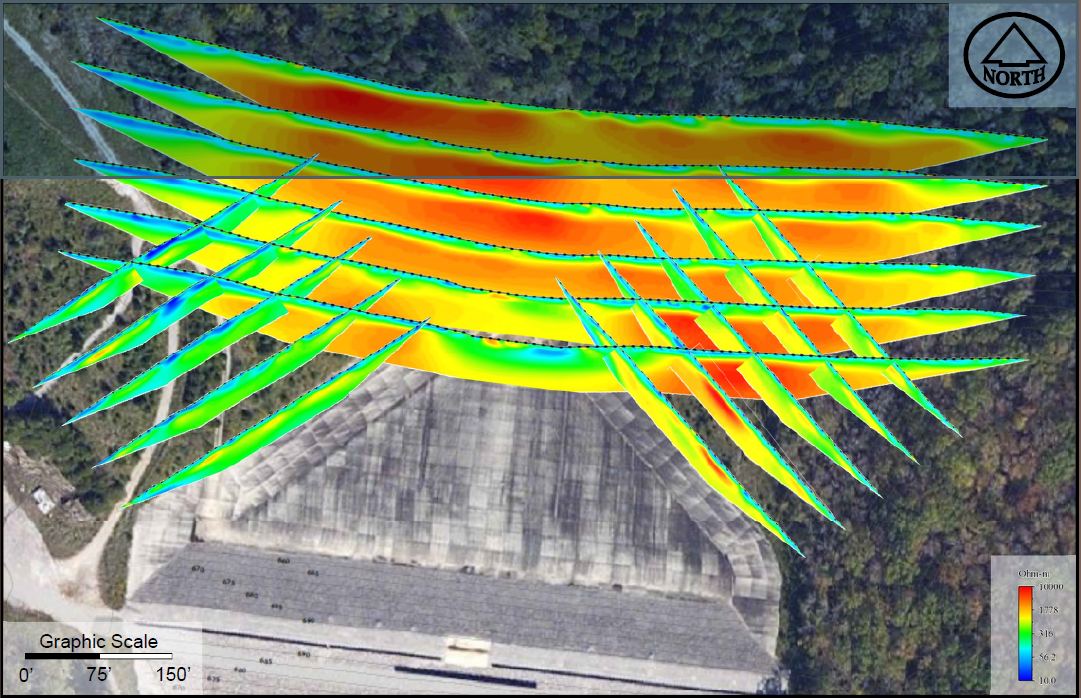

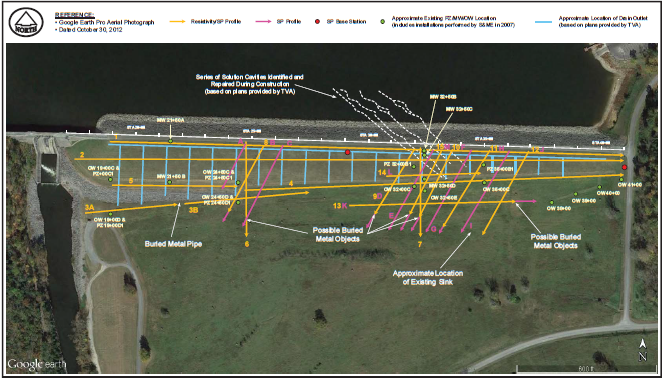

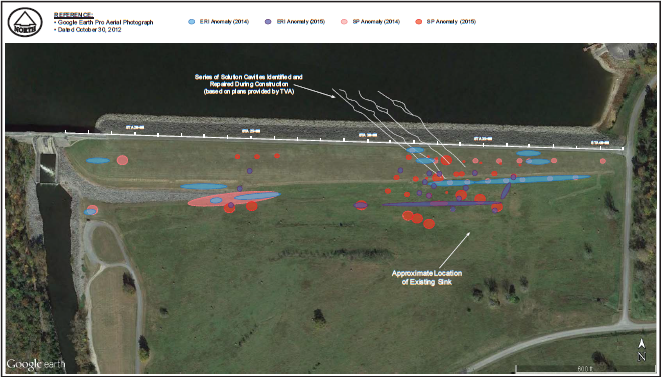

Seepage also posed risks to the continued safe operation of the saddle dam and associated fuse plug at the project. Along with an extensive drilling program, surface and borehole geophysics were conducted at the saddle dam to identify potential seepage paths within the underlying karst geology and to assist in the design of an RCC stability berm for the saddle dam. The electrical resistivity imaging and spontaneous potential methods employed at the surface characterized the lateral changes in subsurface materials while optical televiewer, acoustic televiewer and natural gamma borehole surveys imaged and measured the physical properties of material surrounding the boreholes. A ground penetrating radar survey along the face of the saddle dam identified the presence of potential voids directly beneath the concrete face.

Major project features at Center Hill Dam

Cave features such as that shown above are part of the karst landscape at Center Hill Dam

Remediation of karst features at Center Hill Dam

ERI and survey layouts downstream of the Center Hill saddle dam

ERI profiles downstream of the Center Hill saddle dam

Normandy Dam Description

The Tennessee Valley Authority’s Normandy Dam is a water supply and flood control dam founded on limestone bedrock consisting of an earth fill embankment and a concrete gravity dam with a gated spillway. Construction of Normandy Dam began in 1972 and was completed in 1976. The dam impounds Normandy Reservoir and is located on the Duck River at mile 248.6 in Coffee and Bedford Counties, Tennessee, approximately 8 miles north of Tullahoma, Tennessee, and 1.5 miles upstream of Normandy, Tennessee. The Normandy Dam includes the following associated features (listed from west to east): west (right) abutment, concrete gravity non-overflow section, 2-bay gated spillway and concrete apron, concrete gravity non-overflow section, earth embankment section, and east (left) abutment. The embankment section at Normandy Dam is a homogeneous rolled earth embankment approximately 2,700 feet long. The crest of the embankment is approximately 20 feet wide at EL. 895, yielding a maximum height of about 85 feet. The concrete gravity portion of the dam is composed of 13 monolith blocks and is approximately 506 feet long with an approximate maximum height of 114 feet. The top of nonoverflow section is EL. 895. The ogee spillway consists of two 36-foot wide bays each with a structural steel tainter gate.

Geologic Setting

Geologic conditions at Normandy are very similar to Center Hill Dam and include some of the same bedrock geologic formations. However, the intensity of karst formation appears to be somewhat less at Normandy Dam compared to Center Hill Dam. The bedrock geology immediately below the dam consists of the Catheys Formation, which is a thinly-bedded limestone interspersed with bands of blue-gray shale, or the Cannon Limestone, a uniformly-bedded limestone containing thin undulating shale lenses. Joint controlled solution features are common at the project especially in the Cannon Limestone as documented through foundation geologic mapping and construction photographs.

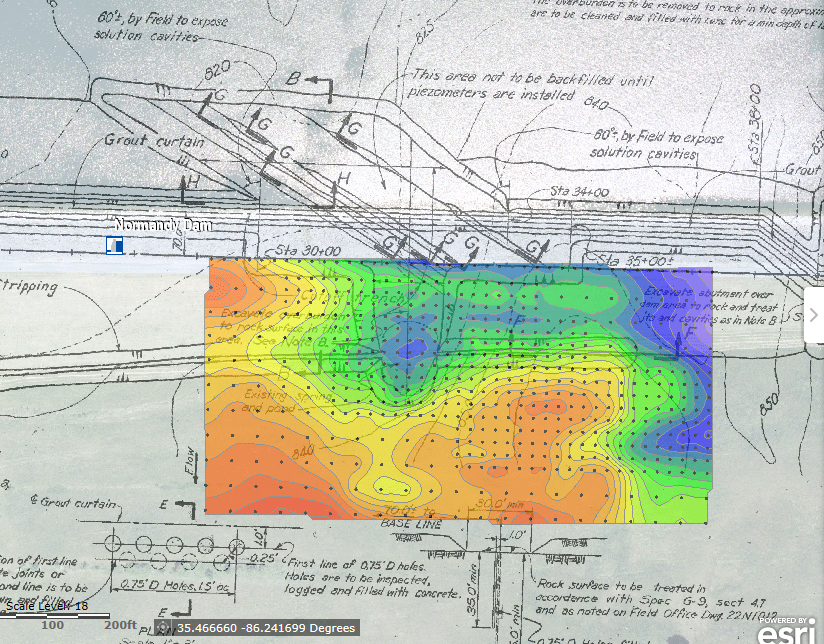

Geophysical Surveys

A site investigation was performed by TVA in 2015 as part of TVA’s Dam Safety Assurance Program. This investigation included geophysical surveys to help determine whether any seepage had developed along the major karst dissolution features since dam construction. The geophysical surveys conducted were microgravity, electrical resistivity tomography and spontaneous potential. While some minor anomalies were indicated on the ERT and SP data, these surveys did not identify any significant anomalies that could be definitively tied to pre-existing karst features. However, the microgravity survey produced results that were in excellent agreement with known karst features that were identified prior to construction.

Normandy Dam - Cutoff trench east of Sta. 35+00 – forming cavities in trench walls, curtain grouting and blasting

Normandy Dam - Location of ERT and SP Survey Lines (2014, 2015)

Normandy Dam - Location of ERT and SP Anomalies (2014, 2015)

Normandy Dam - Bouguer Gravity Map superimposed on Excavation Drawing

Bios:

Jeff Munsey (TVA)

Jeff Munsey has worked for the Tennessee Valley Authority for over 30 years. Most of that time has been devoted to ensuring the safety of TVA’s dams through seismological, geophysical and geological investigations and evaluations. Mr. Munsey earned his B.S. and M.S. degrees in Geophysics from Virginia Polytechnic Institute & State University. Currently, he is the manager of TVA’s Dam Safety Risk and Emergency Preparedness group. He still finds some time to dabble in the geophysical and geological aspects of Dam Safety work and designed and oversaw the geophysical investigation performed at Normandy Dam.

Kevin Hon (S&ME)

Kevin Hon currently works for S&ME and has over 15 years of experience in shallow subsurface geophysics after earning his BS in Geology at Wright State University and his MS in Geology at New Mexico State University. Mr. Hon has spent the majority of his career in geotechnical consulting with a particular emphasis on engineering and environmental applications, however, four of those years were actually working for a manufacturer of geophysical systems. He currently serves as the geophysical group leader and technical lead for geophysical applications within the company.